Hammer enamel: types, manufacturers and applications

When painting metal surfaces, it is important to choose a composition that not only provides the aesthetic appeal of the base, but also protects it from moisture, high temperatures and negative natural factors.

In full measure these requirements are met by hammer paint, which can be applied even on top of rust.

Special features

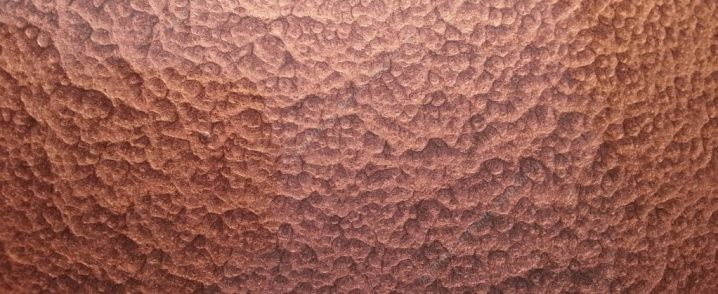

Hammer enamel is a coating used to protect metal structures from the appearance of traces of corrosion, as well as masking minor surface defects. Besides metal, the composition can be applied to concrete, plastic and wood surfaces. After hardening, a strong layer with a hammer effect is formed on the surface.

This is such a coating that mimics hand-made,using a blacksmith's hammer, chasing metal. It is noteworthy that the formed layer is completely safe from the point of view of environmental friendliness.

In addition to the interesting appearance, the product is characterized by high technical properties:

- It is characterized by increased reliability due to the presence of acrylic, acrylic-styrene and epoxy elements in the composition. In addition, there are aluminum powder and crumb glass fines, silicone oil. This causes good indicators of enamel adhesion, polymerization efficiency and high strength properties of the stiffened layer. Crumb glass, silicone and aluminum powder provide improved performance moisture resistance of the composition.

- In addition to these qualities, thermal resistance is characteristic of hammer enamel, the operating temperature of the coating can reach + 80 ° C.

- It should be noted, and ease of application of the mixture. It does not require prior removal of rust and primer base. Easy to apply with a brush or by spraying an aerosol, it does not emit an unpleasant odor, dries quickly (about 2-3 hours), does not stick and does not attract dust and dirt when it dries.

- The coating is operated for up to 3 years, without requiring updating. According to the manufacturers, the color of the coating is maintained for 5 years. White enamel does not turn yellow, colored - does not lose its hue intensity.

If the decorative qualities are not important, and the priority is exclusively anticorrosive protection of the surface, you can not update the enamel layer up to 8 years.

Scope of application

Consider the main uses:

- The weather resistance and moisture resistance of the composition allow it to be used for outdoor work, including in regions with a harsh climate. The environmental safety of the composition makes it permissible to use it when conducting work indoors. The enamel covers the elements of decoration, furniture, fittings, construction of a radiator of heating.

- Vibration resistance allows the use of enamel for application to industrial equipment, the body part of machine tools, paint surfaces located near highways, railways and railway stations.

- The ability of the material to repel pollution and the attractiveness of the enamel coating make it possible to cover garage doors, fencing gates, and entrance doors.

- The moisture resistance of the mixture provides reliable corrosion protection of the elements of flagpoles and drains covered with enamel. It is used to enhance the strength and decoration of the external parts of safes, metal cabinets for various purposes.

The attractiveness and original appearance of the enamel layer cause the product to be applied on plastic, wooden or glass surfaces of terraces and gazebos, forged elements. The latter, thanks to the coating, become even more sophisticated, gaining a pleasant gloss.

Popular brands

- Enjoys popularity enamel with the effect of embossing ML 165. Like all hammer formulations, it is durable and moisture resistant, pronounced anti-corrosion properties. Feature - higher heat resistance. The maximum allowable operating temperature reaches 130 ° C. The composition is universal, has no restrictions on the type of surface and operating conditions. If necessary, remove the layer of enamel of this brand, you can use a solvent xylene.

- If you need to get the color recommended enamel EP-1323 MEthat can be applied to rust.It allows priming and decorating surfaces. It is used mainly for applying to the surface of automotive components, parts of loaders (housing), gates, fences. Compounds 648 and 667 are recognized as an effective solvent for the material.

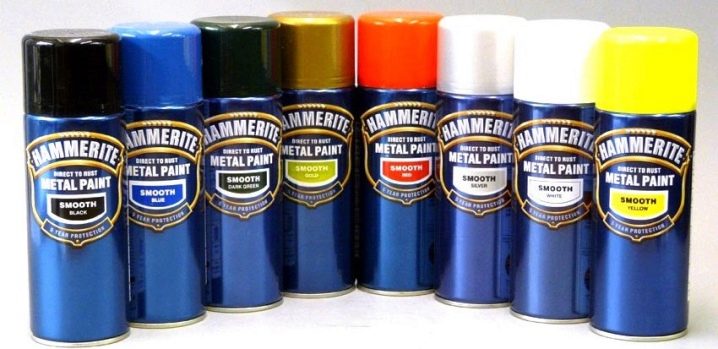

- Among the enamel premium segment worth noting Hammerite brand products. It is characterized by high rates of durability, which means that you can even paint rusty bases.

- If you are looking for an inexpensive composition, pay attention to NTs-221. However, it should be borne in mind that it is rather a decorative coating, it can not be applied over rust. Indicators of moisture and heat resistance of the composition does not exceed the similar values of conventional dyes for metal. Prestige enamel has the same characteristics.

- Hammer compositions for metal products have a different form of release, but the most convenient to use are aerosol enamels. The leading manufacturer of such products is considered brand Bosny. The highest quality paint and convenient, economical, thoughtful design of spray - this is due to the demand for products. It is important that the composition contains no mercury and other toxic elements.

- An interesting effect gives enamel aerosol Hammerite effect. The painted bases acquire a pronounced shagreen effect, a noble matte sheen. The composition is allowed to be applied over rusty bases, however, if we are talking about a thick layer of loose rust, it is recommended to clean it off.

- If necessary, apply enamel with a thin layer on uneven surfaces, products with many small details, choose products from Italian manufacturer Maimeri Idea Spray. Thanks to high-quality spraying and a special concentration of enamel, good hiding power and adhesion of the product are achieved.

- Hammer enamel Dali 3in1, reviews of which are mostly positive, are also suitable for applying on top of rust, as well as on new and already painted bases. It does not require special training, even when used on surfaces made of colored, galvanized and stainless materials. Good hiding power and economical consumption allow you to simplify the process of painting and reduce costs.

- Formula 3 in 1 (that is, high rheological performance, protective and decorative effect) is also characteristic of the composition "Moloteks". Conveniently, the product is produced in containers of different volume, to achieve the strength of the layer, its thickness of 80 microns is sufficient.

Secrets of the application

Covering new products, it is necessary to conduct their preparation:

- First of all, with the help of solvent or white spirit, factory lubricant is removed, then the surfaces are wiped with acetone. It is important to ensure that the grease is completely removed. To do this, attach to the surface of the filtered paper. When fatty spots appear on it, the procedure is repeated.

- Already painted surfaces do not need special treatment. It suffices to remove peeling particles of the coating and remove dust from the surface.

- When using enamel over galvanized, aluminum bases, as well as surfaces from non-ferrous metals and stainless steel, the primer for non-ferrous metals is pre-applied.

- To get the hammer effect on wooden surfaces will be possible only in the case of pre-treatment with acrylic primer, diluted with water.

- Most formulations are suitable for coating on top of rust. However, its loose layer is recommended to be brushed off with a metal brush or using special powders.

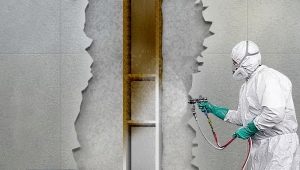

Work related to the application of enamel can be carried out at a temperature of + 10- + 25 ° C and humidity indicators not exceeding 85%.The thickness of the layer should not exceed 100 microns. If you need to create a 2-3 layer coating, you must allow the previous layer to dry completely and only then apply the next one.

It is important to thoroughly paint over corners and other difficult surface areas., as they are more susceptible to corrosion. If necessary, make the consistency of the composition more liquid, enamel is diluted with special solvents. Ideally, enamel and solvent should be of the same brand.. After mixing with the solvent, the composition is thoroughly mixed or shaken.

For airless spraying or roller application, the enamel and solvent should be mixed in a 9: 1 ratio, when using a pneumatic spraying - in a 2: 1 ratio.

Brush application rarely requires the addition of a solvent. The composition in the cartridge is completely ready for use.

How to paint metal with Alpina hammer paint, see the next video.