Silicone enamel: types and characteristics

Among the huge variety of paints and varnishes, silicone enamels differ in a number of unique properties. They are popular not only in the construction industry, but also in other industries. Silicone paints are able to protect any surface from the harmful effects of the environment.

Features of the composition

Silicone enamel has properties that allow you to use this type of product where you need to ensure the best quality and maximum durability of the painted surface. Enamel has a water-repellent effect, and also has immunity to temperature extremes, due to which It can be used in conditions of maximum and minimum temperatures.

The composition of the sun is also not terrible, even with prolonged exposure does not change the original shade of the surface and its inherent technical characteristics.

Enamels are obtained by a synthetic method based on oxygen from air and silicon. This composition gives a special strength and reliability of the design. The composition of silicone materials have special impurities to prevent corrosion, which allows to improve the quality and resistance of the painted surface to the effects of adverse factors.

By adding acrylic resin and cellulose ethyl ether to the composition, manufacturers have achieved quick drying of the painted surface. Carbide layers in the paint composition provide sufficient hardness of the coating, they also prevent mechanical damage to the surface. Thanks to the enamel compounds with epoxy resins, resistance to the negative effects of chemical agents has emerged.

The color gamut of expanded pigments, which are also part of the enamel. They withstand ultra-high temperatures up to 150 degrees, while not losing their original shade. Silicone enamels, in addition to their unique properties, have advantages and disadvantages compared to other types of paint and varnish products.

The main advantages include:

- thermo and frost resistance;

- resistance to high humidity;

- moisture resistance;

- fire safety;

- UV resistance;

- resistance to chemical reactions;

- wide color palette;

- small consumption in the process of painting;

- ability to work at sub-zero temperatures;

- corrosion protection.

Material Disadvantages:

- the release of toxic gases during the drying of the composition;

- with prolonged contact adversely affect the body.

Also, organosilicon materials differ relatively low price. They do not require a primer to be painted. Many other types of paint do not have this feature.

Species

Enamels on a silicone-based basis are usually classified as limited heat-resistant and heat-resistant.

Limited heat resistant

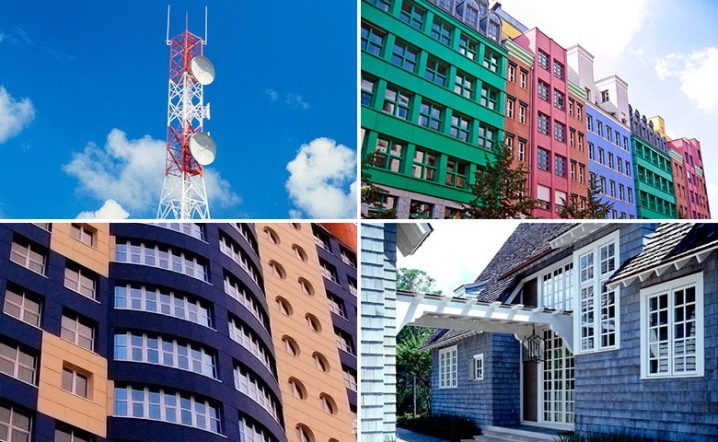

They have been used for facades. The restriction of the enamel is imposed due to the content in the composition of the pigments, giving the desired shade to the paint product. Many pigments do not withstand exposure to high temperatures, so they are called limited heat-resistant.

But this type of enamel perfectly resists the adverse effects of the environment and serves up to 15 years.It is important to note that many pigments in the composition of enamels allow you to increase the resistance of the coating to the effects of ultraviolet rays.

The limited heat-resistant enamels include: KO-983, KO-174, KO-198, KO-168, KO-42, KO-5102. Coatings based on such materials have high physicomechanical characteristics, lack of water absorption, moisture resistance, good adhesion to metal, ceramic, glass surfaces, resistance to sunlight, temperature stresses and environmental friendliness.

Enamel does not form a sediment during long-term storage and during transportation, it is easily applied to the surface with any tools. The main advantage of the limited heat-resistant formulations is the possibility of applying at low temperatures.. At the same time, their service life in a harsh climate is up to 10 years.

Silicone enamels are produced in the form of a suspension of pigments and fillers with a solvent in the silicone material. Products are conveniently transported in any way in accordance with the regulations for the transport of goods at temperatures above 0 degrees.

Before applying the paint should be thoroughly mixed and diluted with a solvent (toluene, solvent 646, orthoxylene).

Also do not forget to treat the surface with a special composition to impart strength and primeds All irregularities are eliminated with a putty, and after drying it is necessary to prime the surface again. Coloring is carried out at a temperature not higher than 20 degrees. The enamel is applied in several layers with drying of each layer for 15-20 minutes.

Paint consumption per 1 m² is 200-250 grams with a coating in one layer, and with two-layer painting - 450 grams. The shelf life of limited heat-resistant enamels is 1 year.

Heat resistant

Enamels are introduced into the composition of anti-corrosion paints intended for painting surfaces that are exposed to high temperatures and high humidity. Often heat resistant compounds used in construction and repair, for painting chimneys, fireplaces and stoves.

Heat-resistant silicone enamels, in turn, are with high hydrophobic characteristics. Such enamels are designed for application to slate, the foundation for protection from efflorescence.

Thermally resistant enamels on the basis of silicone include: KO-8111, KO-8104, KO-8101, KO-814, KO-868, KO-870, KO-813, KO-818, KO-83, KO-88, KO- 89, KO-84. All of them have long-term heat-resistant properties (up to 600 degrees). They are used to apply on metal and other surfaces.: for painting fireplaces, chimneys, barbecues and other structures that are exposed to prolonged exposure to high temperatures.

Often heat resistant compounds are used in the oil industry.: for painting pipelines with superheated steam, oil pipelines, gas pipelines, chimneys and other structures exposed to high temperatures and aggressive media with oils, oil products, salts.

Enamels are available in different colors: silver, gray, white, brown.

Before applying the composition is recommended to shake the jar until the mixture is homogeneous, then measure the viscosity. If necessary, it can be diluted to the desired values. Solvents used are: solvent, toluene, xylene, and solvent 646.

Consumption per 1 m² is 100-130 grams at high temperatures, and at atmospheric conditions and low temperatures - 140-180 grams. The shelf life of heat-resistant enamels is 1 year.

Also in industry use anti-corrosion enamel KO-811 to protect titanium and steel surfaces. They are available in green, black and red. The enamel recipe includes resin-asphaltene substances, special fillers to preserve all the positive properties of paint during storage.

Anticorrosive compounds withstand the temperature range from -60 to 400 degrees. Coating KO-811 has increased protection against weathering and is resistant to corrosive substances.

When applying such enamel, it is not necessary to pre-primer, but the coloring process is carried out in strictly factory conditions, including at sub-zero temperatures. Apply the composition with the spray gun in two layers. The enamel consumption per 1 m² is 100-130 grams. Solvents are solvent, toluene, xylene. Shelf life - 1 year.

Consumption

170-250 grams of enamel are necessary for double surface treatment per 1 m². Depending on the porosity of the surface, the flow rate may vary somewhat. In heat-resistant paints consumption is much less, because they are applied to the surface of the metal, which is not able to absorb enamel.In this case, 150 grams of enamel per m² will be required.

Scope of application

Due to its unique properties, silicone enamels have gained a good reputation in the field of repair, construction and finishing works. During the construction of buildings, silicone paints not only provide reliable protection against negative factors, but also decorate the walls of structures under construction.

Due to the availability and extensive capabilities, organosilicon compounds are also used in metallurgy, nuclear energy, port construction, power plants, machine-building, shipbuilding, chemical industry, gas and oil refining industries, pavements, waterproofing and hydraulic structures. Such compositions are applied to trunk pipelines and plaster, bridges, brick structures, oil pipelines transporting refrigerants.

In the food industry, silicone enamels have also found application, but there are some sanitary requirements for painting surfaces.

According to these standards paint products are divided into the following types:

- paints that can be applied to all types of surfaces;

- materials with restrictions.

Silicone paints of the first type used in schools, kindergartens, clinics. Perfectly are suitable for coloring of kitchen, the dining room and other rooms. Established standards allow you to use them safely without restrictions.

Silicone enamels of the second type used only for certain jobs that are permitted by sanitary requirements. A list of possible applications of such compositions can be found on the label of the package of a paint and varnish product.

Application Tips

Paint with the use of silicone compounds applied to the painted surface in compliance with the technology of painting works:

- Surface preparation. If the surface is metallic, it is necessary to remove dirt, dust and rust. After removal, proceed to the surface degreasing with solvents. The surface is cleaned either manually or mechanically.

If necessary, the surface can be primed in several layers, if the mixture is compatible with silicone enamel.

After applying the primer mixture, it is necessary to allow the surface to dry completely, as silicone paint can not cover a wet surface.

- Preparation of coloring compositions before application. Silicone compounds are sold in ready-to-use form. But if for some reason the mixture was too thick, it is diluted with toluene and xylene, and then the solution is thoroughly mixed.

To reduce consumption, it is impossible to dilute the enamel, since in this case the resulting film will not be strong enough and of high quality.

- Enamel coating. The painting composition can be applied with an airbrush, brush, roller, airbrush. Coloring is carried out within temperatures from -20 to +40 degrees. But the most important condition is that the paint is applied on a dry surface.

Enamel is applied on a metal coating in two layers, and on concrete, cement and brick - in three. After applying each layer, you must give time to dry the coating.

The most important parameter that must be controlled when applying enamel to the surface is the thickness of the film formed. The best option is 40-50 microns.For quick drying, experts advise the use of airflow or infrared heaters.

For tips on using silicone enamel, see the following video.