Alkyd enamel: characteristics and scope

Alkyd enamel is one of the best paints, as it has excellent performance properties. High technical characteristics of this mixture make it universal. It is necessary to consider in more detail the main characteristics and scope of alkyd enamel.

Special features

Alkyd paints and varnishes have long been present in the construction market. Despite the constant appearance of new modern paintwork materials, this mixture does not lose its popularity. Alkyd compounds differ in low cost and excellent performance.

These mixes are universal and can be used both indoors and for street constructions, as well as are available in a wide color range.

The alkyd mixture is primarily distinguished from other paint and varnish coatings by high drying rate, long service life and elasticity.It is also worth noting that this coating is highly resistant to fading or loss of color over the entire service life. Other positive properties of alkyd paints and varnishes include the following:

- high resistance to oil products and chemicals. This coating can be washed with the use of aggressive household chemicals;

- resistance to temperature extremes. Properly applied coating can be operated at temperatures from -50 to +60 degrees;

- resistance to any weathering;

- easy to apply;

- has a small expense.

The main disadvantage of alkyd enamels is their toxicity. Paints made on a water dispersion basis are the safest for health and more suitable for interior decoration. However, alkyd mixtures are unsafe only during the finishing work.

If you protect the organs of the respiratory tract respirator and well ventilate the room, the paint will not bring harm to the body.

Composition

The basis of this material is alkyd varnish or resin. In addition to this component, the enamel includes solvents, various fillers,dyes and special additives. White spirit is most often used as a solvent component. As fillers used crushed marble or crushed sand. The consistency of such fillers is a very small fraction.

Special additives most often have some specific purpose, for example, give enamel protective properties against microorganisms, corrosive formations or rotting. As for the main component, alkyd varnish, the following types of material are used:

- on the basis of pentaphthalic resin;

- on the basis of glyptal resins;

- based on melamine formaldehyde resin;

- based on alkyd-styrene resin.

The peculiarity of pentaphthalic lacquers is high speed of hardening and good moisture resistance. Glyphthalic compounds are fast drying. There is no significant difference in the technical properties of pentaphthalic and glyphthalic mixtures. Melamine-formaldehyde mixtures are able to withstand significant positive temperatures (up to +175 degrees).Alkyd styrene solutions are used for processing products from metals and wood.

Types and properties

Alkyd enamels are classified by composition. Each type of coating has its own characteristics and specifications. Special purpose paints are also available for certain types of surface. Each type of alkyd enamel has a special marking consisting of numbers and letters. Marking allows you to accurately determine which category this or that composition belongs to. The letters represent the main component that was used in the manufacture of the material:

- GF - enamel on the basis of glyptal lacquer;

- PF - enamels based on pentaphthalic lacquer;

- ML - melaminoalkidny compositions;

- MS - alkyd-styrene mixtures.

The first number after the letter abbreviation plays the role of identifier of certain properties and purpose of the composition. It is worth considering the values of each digit:

- 1 - this solution can be used for construction work outdoors;

- 2 - this composition is intended for repair work inside buildings. At the same time the absence of heating in the room is allowed

- 3 - enamels are used only as temporary protection (conservation) of various surfaces;

- 4 - this category of alkyd paints and varnishes has a high level of resistance to moisture;

- 5 - enamels, whose composition includes special components, thanks to which the paint has a special purpose. For example, the mixture may scare off rodents or have a luminescent effect;

- 6 - mixtures are highly resistant to various petroleum products;

- 7 - enamels, which have excellent resistance to aggressive chemicals;

- 8 - such solutions are highly resistant to high temperatures;

- 9 - compositions with electrical insulating properties. Such enamels perfectly withstand electrical voltage and current;

- 0 - the mixture is intended for priming various surfaces.

The last two digits in the marking indicate the location of enamel in the general catalog. As well as alkyd compounds are separated according to the form of release. Enamel can be purchased in liquid form in cans or as a spray in aerosol cans. As an example, consider the most popular alkyd formulations.

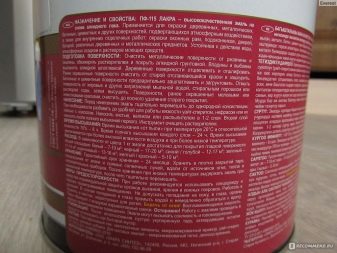

- PF-115. This composition can be freely used indoors and outdoors. Enamel is used for painting structures made of metal and wood, as well as for cement, plaster and concrete foundations. The coating is applied in no more than two layers. The composition dries completely after a day of paint work.

- PF-133. This modification of alkyd enamel is perfect for application to metal surfaces. Coloring has a long service life, which can be 6 years. At the same time, the technical characteristics and appearance of the coating do not change. PF-133 fast-drying enamel is applied on the surface in at least two layers. Dries such a coating for about two hours.

- PF-233. The composition is used for dyeing metal and wood. The mixture is ideal for painting radiators, while the enamel PF-233 has excellent covering properties, it can be applied even on a layer of old paint. Paintwork material has good resistance to high temperatures. The drying rate of the coating is slightly lower than that of other alkyd formulations. Full drying time can reach 36 hours.

- PF-253. This paint and varnish composition is intended for painting radiators and wood floors. Before applying the enamel on the floor covering, wood must first be primed. After the composition has dried, a smooth and glossy coating is formed on the surface.

- GF-230. This enamel is designed for indoor repairs. There are some limitations in the application of this composition: the paint is not suitable for the floor, as it is sensitive to high mechanical loads. To dilute the mixture, you can use white spirit or turpentine. Before complete drying, the coating has a rather sharp smell.

Colors

The color palette of alkyd paints is one of the most diverse among all types of enamels and is not limited to white and black tones. This allows you to easily find the right shade. In addition, you can get the desired color by mixing enamels of different colors. The decorative properties of this material are also significantly higher, for example, compared to no less high-quality acrylic paint.

According to the degree of gloss, both glossy and matte versions of coatings are produced. Spray paint is characterized by the presence of such non-standard colors with interesting effects, such as:

- chrome - most often used for rims;

- with metallic effect;

- with a golden glow;

- paint glowing in the dark.

Scope of application

Due to the wide range of types and universal properties, alkyd enamels are widely used in repair and construction for painting practically any materials. Such coatings can be used for interior and exterior repairs. Most often alkyd enamels are used for painting structures made of metals, wood and concrete. Alkyd-urethane paint for metal structures reliably protects the surface from the influence of negative environmental factors and prevents the formation of rust.

It can be used for painting industrial buildings and household objects, such as radiators.

For machine parts special alkyd enamel is produced. This paint is based on glyptal resins. Alkyd enamel can also cover the body of vehicles.Automobile mixture is applied in three layers, which increases the time of its complete drying. The resulting coating has a high strength and resistance to cracking.

Pentaphthalic paint based resins are excellent for painting floors and walls, as it has excellent resistance to abrasion and mechanical stress. And also such a composition is widely used for processing metal structures for various purposes.

Recommendations for use

Working with alkyd enamels is not particularly difficult. Paint is applied on the previously cleaned base. From the surface it is necessary to wash off all the dirt and degrease. Enamel can be applied with a paint brush, roller or spray gun. In certain cases, it may be necessary to dilute the mixture with a solvent before application. It is necessary to dilute the enamel when the mixture is too thick or in order to save paint.

To obtain a better and more durable coating, an alkyd compound is applied in more than one layer. If repairs are carried out indoors, then good ventilation should be provided in the room.Gloves and a respirator should be used as a means of personal protection.

Manufacturers

The quality of the paintwork material largely depends on the manufacturer of the mixture. Choosing a suitable composition, it is necessary to take into account not only its properties, but also belonging to a particular brand. Among the most popular manufacturers of alkyd paints are two companies.

Lacra

The company "Lakra" is engaged in the production and sale of paints and varnishes since 1996. The company's products are very popular in Russia and neighboring countries. All manufactured materials are of high quality, which is primarily due to the use in the production of the latest high-tech equipment and imported raw materials from leading companies. At the Lakra enterprise several modifications of alkyd enamel are made. In addition to universal compositions for external and internal works, the company produces special-purpose mixtures:

- for wooden floors;

- anti-corrosion coatings;

- for radiators.

All compositions perfectly combine protective and decorative properties.Alkyd-based mixtures "Lakra" have a high level of resistance to negative atmospheric factors and moisture. After complete drying, the coatings do not emit toxic substances and are completely safe for health.

"Tex"

The company "Tex" has proven itself in the Russian construction market as a supplier of high quality paint and varnish coatings. The company has been a leader in the industry for over 15 years. All Tex products are certified and meet international quality standards. The company produces such varieties of alkyd enamels, such as:

- universal purpose;

- for applying to the surface of floors of wood or fiberboard;

- alkyd-urethane composition for concrete floors.

Universal paint PF-115 is suitable for most types of surfaces. You can work with this composition both inside and outside the room. The service life of the coating is five years. Enamel "Tex" for wooden floors is marked PF-266. This modification is highly resistant to mechanical stress, abrasion and household chemicals.

Mix for concrete floors designed specifically for use in rooms with high traffic.

From the following video you will learn all about the advantages of alkyd enamels over other types of paints.