Entrance doors to the apartment with noise insulation

A home is a place where, after a long and tiring working day, you want to feel as comfortable as possible. Many factors contribute to this, for example, the optimum air temperature in the apartment and sound insulation. Moreover, the latter should in no case be neglected in order to avoid adverse health effects, because noise is a clear irritant of the nervous system that can affect the speed of reactions and the psycho-emotional state of a person.

The perfect solution to insulate the apartment from getting too much noise is to install noise insulation doors.

The presence of cloths with a soundproofed construction of high-quality design ensures that the penetration of extraneous sounds from the outside will be impossible.

Special features

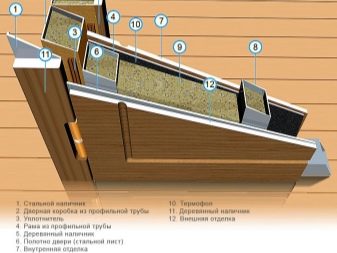

Soundproof entrance doors consist of several layers, which does not allow excess noise to penetrate inside. The design of such models, regardless of the material of their manufacture, is placed high-quality sound insulator. Similar products are usually installed:

- in offices where the execution of work requires a high concentration and concentration.

- In public institutions, where a constant stream of visitors creates noise from communication. In addition, it happens that the conversation between employees takes place in a raised voice, which also should not go beyond the door of the office.

- In hospitals and clinics, where the level of responsibility of workers does not allow them to be distracted by extraneous sounds and noise, which often emanate from hospital corridors due to the mass gathering of people there.

- In apartments (especially multi-storey), where you want to isolate yourself as much as possible from external noise, conversations of neighbors in the stairwell, and the sound of opening and closing neighbour's doors.

The following factors provide good sound insulation for the front door:

- soundproofing material for.

- Door leaf depth

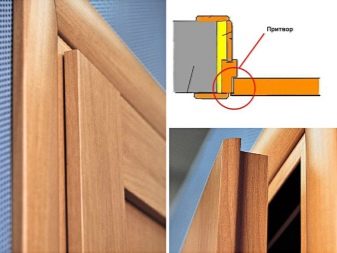

- Lack of gaps between a cloth and a box.

- The presence of a fixed seal around the perimeter.

- Installing the lock, eliminating through holes

Sound insulation materials

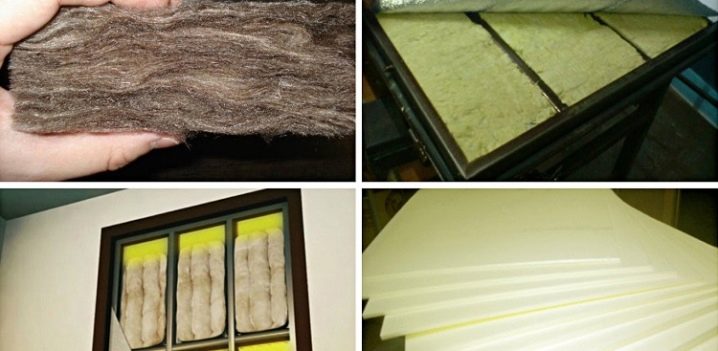

For the smallest percentage of the penetration of external noise into the apartment, multi-layer doors are used. Usually, the most popular materials for filling canvases are:

- Mineral wool. Excellent material both for warming, and for sound insulation. It is easy to install, but needs protection from moisture. The design of the door becomes heavier due to the installed additional stiffeners, which reinforce the door frame.

- Styrofoam. One of the most affordable door fillers. A distinctive feature - low weight and high density, which contributes to good sound insulation. However, it is worth remembering its flammability and smoke during combustion. Experts do not always recommend purchasing doors with foam filler due to their low fire safety.

- Polyurethane foam. In terms of its functions, it competes with mineral wool, but it differs favorably due to its snug fit to the surface of the web and preserving its shape and resistance to fire.

- Corrugated board. The most affordable option offered, however, is most often used in low-cost doors, and does not always satisfy the needs of high-rise residents for protection against noise.

The entrance door with noise insulation of several layers of different materials that complement each other, makes the properties of the structure and its functions the most effective. The system is equipped with special thresholds and contours, due to which the door leaf is pressed tightly against the box, which contributes to the improvement of sound-insulating functions.

It is worth noting that only the built-in internal noise insulation materials is hardly enough. The door is also sealed along the entire perimeter in several layers, using foam rubber or plastic ribs.

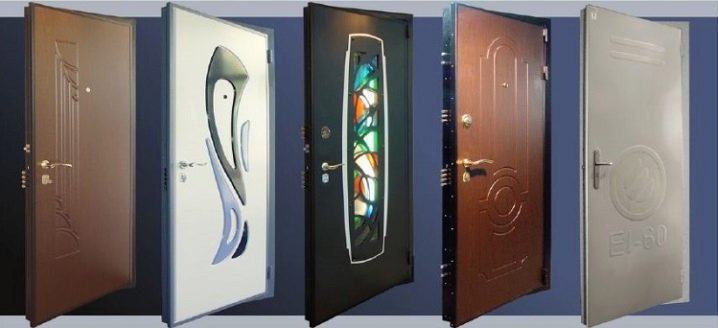

Models

For the manufacture of using two types of material: wood and steel.

Metal is a good conductor of extraneous noise.Therefore, in the process of production, doors made of steel are given additional noise insulation by adding various sound insulation materials mentioned above. Back in Soviet times, when metal models only gained their popularity, but did not differ in good quality, they had to install second canvases to avoid excessive noise penetration into the room.Over time, the entrance door of such a material has changed, becoming more "deaf" and durable.

The production of these models begins with the welding of a large frame, in the middle of which is placed insulating material with high-quality sound insulation. It is installed between two sheets of metal, filling the U-shaped ribs. In addition, inside the U-shaped ribs of the metal frame, the level of noise absorption is improved by MDF panels or vinyl artificial leather. Powder coating helps prevent mechanical damage. The door with this treatment looks much more original, and it is very difficult to damage it.

With wooden doors, everything is much simpler, since the tree itself is sound absorbing material. Also, the level of sound insulation of such doors affects their thickness. The thicker the product, the better the insulation. The most common types of wood for the manufacture of entrance doors are oak, walnut, ash, cherry and some conifers. Such an eco-friendly product is able to regulate the humidity-temperature balance of the room. For coloring use various kinds of dyes (sometimes varnished).

There are many interesting moves in the design development of models of entrance doors. One of the most original and unusual design options is the design with built-in mirror.

In addition to the execution of its direct functional purpose, such a detail can visually expand the space of the room.

Is it possible to soundproof your own hands?

You can carry out work on soundproofing the door yourself. The first thing you need to know is whether the doors are collapsible. If so, then after removing the inner sheet of metal, the cavity is filled with soundproofing material and fixed with adhesive.

If the construction is still not divided into parts, then it is possible to do work only outside. Such products are assembled from two metal sheets that are welded to the frame in advance. The door is trimmed with soundproofing material from two sides, then made additional exterior trim to give the model a neat appearance:

- In the first case (with collapsible doors), the sound-absorbing material is fastened inwards with the help of special nails or special glue.After that, the inner canvas is set in its place.

- In the case of a construction that cannot be disassembled, roll-on heat insulators with a sticky backing are used, perfectly attached on both sides of the door leaf. After that, skin is made over the layer with the material, which gives the product a presentable look.

It is important to remember that it is necessary to eliminate any gaps and gaps between the door leaf and the box. The establishment of an additional threshold is desirable for high-quality soundproofing.

Manufacturers Overview

As a rule, the highest quality products are produced by factory manufacturers who care about the reputation and the quality of their products. Consider the rating of domestic manufacturers:

- entrance doors The Guardian. The company, which for its fifty-year experience has been able to win the trust of consumers and a good reputation in the market. This manufacturer is rich in positive reviews. One of the important moments is the guarantee of heavy-duty protection. Two-millimeter steel is installed on any door models, and locks made of the safe type guarantee safety and confidence in reliable protection against unwanted guests.

- Entrance doors Torex. The company operates for about 17 years and boasts a large number of positive reviews. The doors of this manufacturer are distinguished by their good thermal insulation and noise insulation qualities. However, the disadvantage of the company, according to some consumers, is the use of Chinese components in the manufacture of door products.

- Entrance doors "Condor". The company is famous for its excellent design solutions and unique solutions for its aesthetic value. Doors "Condor" easy to install and have good burglar resistance.

- Firm "Squirrel". The range includes a huge selection of materials for the exterior. Door designs comply with the latest standards, both in appearance and in their performance. BelKa models meet the requirements of burglary resistance of all classes.

How to choose?

By the choice of the front door with sound insulation should be approached seriously and carefully, because first of all - This is the protection of our home:

- The first thing you should pay attention to is the quality of the material itself, from which the door leaf is made, as well as its thickness.The density of the design is an indicator of fullness of sound-proof material. In general, it ranges from 50 to 130 cm.

- Also one of the most important factors is the properties of noise insulating and heat-insulating filler of the door leaf, because the functioning of the product directly depends on this. Cheap, flammable material is not worth the cost to the buyer. It is necessary to study this question in detail.

- Noise insulation of the door has the best performance in the case of processing the door contour seal, running along the perimeter of the canvas. However, this should be the measure. One seal is small, three is already a lot. Two seals are sufficient for the effective functioning of the product.

How to improve?

The most effective option to improve sound insulation is to install a second door, which will greatly help get rid of noise. If the goal is to improve the sound insulation of an already existing structure, then the first thing to do is to find problem areas on the old canvas and eliminate them, isolating them with special insulating strips.

By maximally reducing the gap between the door frame and the opening, you can increase not only sound, but also thermal insulation:

- To find the damaged areas, you can insert an A4 sheet into the gap between the metal sheet and the box, holding them up and down. This will indicate gaps that need to be fixed.

- Recently, to blow out unnecessary slits, use mounting foam. Also, you can use adhesive insulating tape, which is glued around the perimeter of the product and helps to soundproof the metal door.

- There are special strips that are attached to the door, improving its insulating qualities. They are attached to the box with liquid nails.

- Also installed special thresholds to the bottom of the door, which help protect the space from the penetration of unnecessary sounds.

- Sometimes people pamper metal structures with wooden chipboard. In this case, the thickness of the finish should be at least 1.5-2 cm. To improve the aesthetic qualities of the door, you can use MDF or ordinary wall paneling.

As you can see, the sound insulation itself or the improvement of the quality of sound and heat insulation does not require special skills. It is simple and accessible to everyone.

How to check the sound insulation and tightness of the front door, see the following video.