M400 cement: pros and cons

For the construction of modern private houses and industrial and defense facilities, builders use cement mortars. Each type of cement mixture has its own individual characteristics and is used at different stages of construction work.

Cement mixture M400 - demanded type of building material used for the construction of residential and industrial premises and the execution of works on finishing and masonry. This brand of cement is used not only by Russian construction companies, but also by organizations from Europe. High strength, resistance to temperature and moisture, a long period of operation made this building material a leader in the sales rating of building mixes for concrete production.

Special features

M400 cement is an artificial mortar that acquires a thick, saturated, paste-like structure when combined with a liquid.This type of cement belongs to the group of inorganic binding mineral compounds that have a comfortable grinding fineness and an optimal fraction of particles. The reaction between chemical elements turns a mixture of sand and cement into a solid building material that has similarities with stone.

The main feature is resistance to sulphate environments and corrosion. Cement M400 brand is a binder component for various building mixtures. Clinker for the solution is obtained by burning limestone and clay.

For the manufacture of cement brand M400 using minerals such as alit, alumina, magnesite, gypsum. To impart individual properties and technical characteristics to different brands of cement, additional components are added to the solution, the amount of which is established in production standards and norms. Additives added to the solution increase the plasticity, frost resistance and resistance of the mixture to the negative influence of the environment. Their number should not exceed 5 percent of the total mass of the solution.

The properties and technical characteristics of this brand of cement allow to work on industrial objects:

- highways;

- hydrotechnical and underwater structures;

- ground and underground objects.

The solution is widely used for the construction and installation of reinforced concrete structures.

In civil engineering, the material is used for the installation of various types of foundations, the construction of walls and columns, the production of mortars for plastering various surfaces, the arrangement of walkways and sidewalks, and the manufacture of concrete grades from M100 to M450.

Advantages:

- universality;

- convenient packaging;

- high strength;

- resistance to low temperatures and moisture;

- long period of operation;

- possibility of use in different climatic zones;

- wide scope;

- absence of cracks and chips;

- affordable price.

Disadvantages:

- the inability to use for the construction of multi-storey buildings.

Specifications

Cement mortar brand M400 has individual technical characteristics:

- the solution consists of 97 percent of inorganic components, the main of which are oxides of calcium, magnesium, titanium, aluminum, iron, silicon;

- physical condition - solid;

- the cement construction can withstand a pressure of at least 400 kg per 1 cm² of the total area;

- bulk density in the unconsolidated state ranges from 1100 kg to 1500 kg per 1 m³;

- temperature range is from -30 to +300 degrees Celsius;

- partial hardening of the solution occurs after 4 hours, and the full set of strength occurs after 1 month;

- water resistance is not more than 25 percent;

- maximum adhesive characteristics appear after a full set of strength;

- the period of operation is at least 100 years;

- has high resistance to organic and inorganic solvents.

Cement manufacturers emit several groups of the mixture, depending on the components in its composition:

- Portland cement (HRC). It is made of calcium silicates, characterized by a wide scope. It has an average curing rate and high technical parameters.

- Aluminous Cements (HZ). Made from aluminum, calcium, iron, silicon and their oxides. Quality standards are set by GOST 969-91. They have high speed of hardening and full hardening. Used for construction of objects in regions with low temperatures.

- Cements magnesia (MHZ). Contain a high percentage of magnesium. Designs from this solution have a high percentage of density and a long period of operation.

- Pozzolanic Cements (PPC). Made from small inorganic compounds of volcanoes. In production, substances with increased viscosity are used (silica and alumina mineral components, slag and fly ash).

- Portland slag cement (SHPTS). It is made from slags of blast-furnace production. It has a low price and is used in aggressive environments and mineral waters.

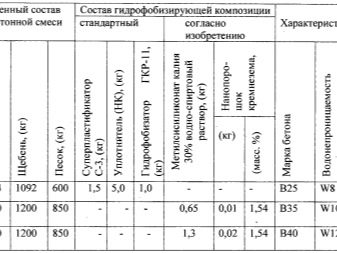

To obtain a high-quality concrete solution, it is necessary to strictly observe the proportions of water, cement, rubble and sand. Violation of technological standards in the dilution and mixing of the components will result in poor quality concrete. To prepare 1 cube of concrete M200, you must use 500 kg of cement M400.

All technical characteristics and their descriptions, date of manufacture, shelf life, storage conditions, methods of connecting components and dilution of the mixture to obtain high-quality concrete mortar manufacturers in full indicate on the packaging bags.

Manufacturers

Producers from different countries of the world produce cement of the M400 brand, but Russian goods are of the greatest demand among buyers due to the fact that they have high quality that meets European standards and an affordable price.The building material is produced according to the quality standards established by GOST 31108-2003.

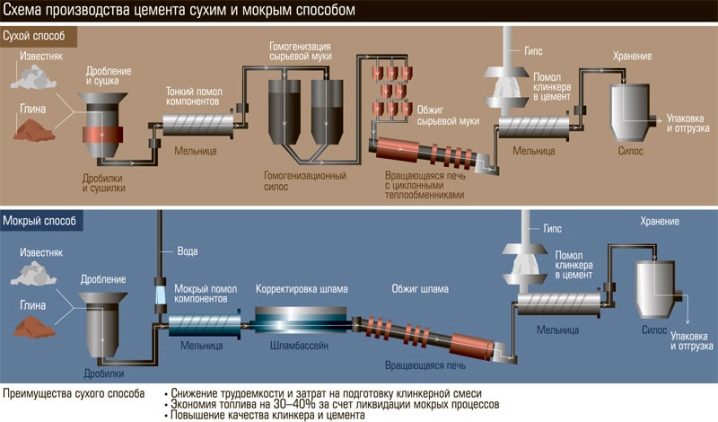

For the production of cement brand M400 manufacturers use several methods:

- wet - grinding elements of the mixture in water;

- dry - production of building material without the addition of water, is the most popular and economical method;

- combined - provides for the simultaneous use of dry and wet methods.

On the shelves of hardware stores you can find several types of packaging:

- packages weighing 1 kg;

- bags weighing 25 kg and 50 kg;

- bulk.

Cement, packaged in bags and bags, suitable for small-scale construction: it is convenient to store, plant, move and keep track of consumption. To perform large volumes of work builders acquire bulk material.

On the packaging, manufacturers indicate the full information about the product by labeling.

Marking on the percentage of additives:

- D0 - has high waterproof performance, used for the manufacture of structures of reinforced concrete;

- D20 - contains no more than 20 percent of inorganic additives, used for the construction of defense and civilian objects,the manufacture of plates, blocks for the foundation and beams for floors, has a high water resistance;

- D-20 B - high-speed mortar having high strength and ductility and used for the manufacture of structures made of reinforced concrete.

Composition marking:

- CEM 1 - clean cement;

- CEM 2 - cement with additional components (group A - percentage of additives not less than 20, group B - percentage of auxiliary elements not less than 30).

Marking of individual qualities of the solution:

- SS - sulphate resistant;

- Gf - hydrophobic;

- B - quick-drying;

- BC - white cement;

- H - normalized;

- Submarine - plasticized;

- VRTS - fast-setting.

Cement M400 brand has a strength class of 32.5 MPa.

Tips and tricks

By purchasing this building material, experienced builders recommend to follow a few rules:

- to perform small-scale work, it is necessary to purchase cement in bags from 1 kg to 25 kg;

- when buying a material, it is necessary to check the date of manufacture and manufacturer;

- It is necessary to comply with the technological standards of transportation and storage;

- material shelf life in bags - no more than 6 months, in plastic packaging - 1 year;

- cement in bags is of high quality, well protected from moisture penetration and negative environmental effects;

- high-quality cement should have a gray color, crumble and not stumble into one;

- most demanded cement has particles with a fraction of from 40 to 80 microns.

An important role in the purchase of any building material is its price. In order to objectively evaluate the pricing policy of the selected building store, you must know the indicators that make up the price of the goods:

- a high percentage of mineral additives will significantly reduce the price;

- the addition of plasticizers increases the cost of the goods;

- fine grinding of the components of the mixture will increase the price range;

- the cost of cement depends on the country of origin and transportation costs;

- packaging material and its quality are included in the cost of the purchased goods.

Cement is a universal building material with a wide range of applications in private, industrial and civil construction. The unique property of this solution to solidify in water expands its area of application and makes it possible to implement projects not only on the ground, but also under water.

Before starting work, experts recommend carefully studying all the technical characteristics and material properties., experienced consultants from specialized construction stores will help you make the right choice and purchase the right cement brand.

Only the use of high-quality construction mixtures of famous manufacturers will allow you to create durable and durable structures and structures.

To learn how to knead cement mortar, see the following video.