Features of the block house with imitation timber

Over the years, wood has been one of the most sought-after materials in the construction and finishing industry. One of its versions is a block house with imitation of a bar. This profile has a number of features, which makes it popular among buyers.

Special features

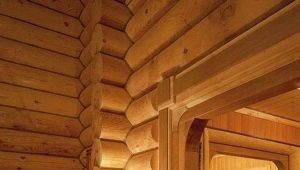

The block house is a sheathing material in the form of a board, which is made from an array of different breeds. It is made by cutting logs with further processing on special machines. This profile is characterized by the presence of locks for installation on the principle groove-comb. It can have different dimensions, while it is very realistic and creates the effect of a structure built from a bar.

The beveled sections of the trapezoidal profile create a docking effect between the bars. Only an experienced specialist will be able to notice the imitation. The shape of this profile is different from the analogue under the log.Externally, the lamella is trapezoidal, while the analogue under the log has a rounded front part. This material allows you to hide thermal insulation material and improve the appearance of the building.

It does not have a large bearing capacity, since it is small in thickness. However, it is precisely because of this ability that these lamellae have a higher risk of cracking in the joints. The profile has a flat and flat face, which makes it easier to care for. To keep such facing clean, it is enough to wipe it with a semi-dry cloth and timely remove dust.

In addition, it is easier to handle if necessary. For example, it is easy to sand and lacquer, and also to be coated with special impregnations to maintain a pleasant aesthetic appearance and prolong its service life. It is possible to use this sheathing material for finishing inside buildings and outside. From the back, it has 2 ventilation grooves necessary to prevent deformation of the lamella.

In the production of these boards are subjected to chamber drying, which reduces the process of getting rid of excess moisture. Usually it takes from several tens of hours to several days. After the material is conditionally "dry", having no more than 15% moisture, it is treated with antiseptics and fire retardant, and then coated with varnish. Externally, this profile looks expensive and impressive, for which he is in demand among modern buyers.

The block house is mounted horizontally. At the same time, shrinkage and swelling of the material occur more in the transverse direction. Changes in linear size in the longitudinal direction are minor. This feature allows the material to be virtually non-shrinking.

However, under no circumstances should an undried board be installed.

Advantages and disadvantages

The block house with imitation of a bar has a number of advantages. For example, it is environmentally friendly because it is executed from an array. During operation, it does not emit toxic substances in the air, so it can be used to decorate different rooms of an apartment or a private house, as well as a summer house. Its cost makes it possible to contrast it with many other sheathing materials. It allows you to give the structure the appearance of naturalness, without hitting the family budget.

Due to its configuration, it promotes natural ventilation beneath. In addition, such a profile in most cases is not subject to rotting and cracking, but durable. If the technology of installation and operation is observed, false-timber will serve for 50 years with wall or ceiling decoration. It is suitable for use in different climatic zones, since it is resistant to temperature changes and does not deform at a temperature range from -50 to + 50 degrees C.

The block house with imitation of a bar is excellent sound and thermal insulation. It will not only reduce the level of annoying noise coming from the outside, but also reduce the heat loss of the room, which will be especially noticeable during the cold season. The use of such a profile will save on heating. In addition, the material is easy to install: it can be installed even by a beginner and does not require special skills in working with wood.

Such coverage allows you to disguise wiring and communications. In addition, it is possible to additionally warm the walls with mineral wool, polystyrene foam or other heat insulating material.This type of wall paneling, with the right approach to the design of the finish, can ennoble the walls, ceiling or even the facade of the house. The wood of each profile has a unique natural pattern.

Due to special impregnations, this board is characterized by resistance to moisture and the effects of rodents, as well as harmful insects. Having natural micropores in the structure, in a trimmed room a favorable microclimate is created, which is important for the health of every household. In addition, such material allows finishing painting, processing by stain or varnish. This allows you to extend its durability.

However, along with the advantages, the simulated block-house under a bar has its drawbacks. For example, due to different percentages of humidity in a particular zone, it can change its linear dimensions. To stabilize wood, it is necessary to resort to various kinds of impregnations, which increase the resistance of boards to moisture absorption. Some varieties of the array are prone to rotting and warping.

Despite the increase in fire resistance of trapeziform lining due to special impregnation, wood supports combustion. If it is poorly dried after cutting and has excess moisture in its composition, it will deform and crack.Moreover, without constant care, this lining will lose the aesthetics of the look and collapse, which in most cases depends on the moisture content of the structure itself.

Almost always in the process of exploitation, the skin becomes dark, so sooner or later the question of its deaf coloring will arise. It is undesirable to use such material in a humid environment so as not to provoke the formation of mold and microorganisms.

If the moisture content of the purchased material is above the norm, the appearance of a blue tint is not excluded, which indicates the presence of a fungus affecting the wet wood.

Sorta

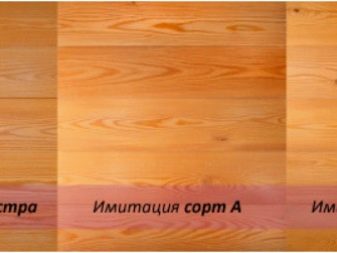

The block house, as well as the entire sheathing profile, is divided into 4 classes: extra, A, B, C. The differences are due to the quality characteristics of the material. For example, the best type of finishing boards under a bar are Extra-class slats. They do not have knots, resin pockets and are characterized by a smooth, smooth surface.

In this case, not even the slightest errors of the tree structure are allowed. Invalid blue, wormhole and even more so falling out knots.

Class A allows for minor imperfections of the back side. For example, it may be a slight roughness.However, neither blue nor cracks on this profile can not be.

Classes B and C inferior in quality to the two analogues described above. However, if the category B material still has basic limitations, class C also allows for the presence of knots, and even through cracks. It is difficult to call such a material suitable for purchase, because the buyer is often unable to view the goods because of its closed packaging.

Despite the fact that the entire profile is sorted for quality, often on the shelves there are a lot of bad raw materials for finishing facilities.

However, it should be borne in mind that the blue, cracks and wormholes will significantly affect the durability and appearance of the lining. Having opened a product at home, you can face the fact of lumber disrepair. It is necessary to take quality products for plating, since it is unlikely that it will be possible to return lower-grade products to the store.

Materials

To date, a block house with an imitation of timber is made from pine, spruce, larch, birch, alder, linden and cedar. The difference between coniferous and hardwood planks determines the degree of their relevance in the decoration of a room.For example, conifers are characterized by the release of resin when heated, as the array structure expands. The heated resin can burn, in addition, products from such an array emit ethers. To use them for finishing surfaces of baths and saunas is undesirable.

Variants of hardwood boards (for example, alder or linden) are more homogeneous structure, due to which they are easier to handle. They have no resin, which simplifies the grinding and finishing of such a profile. In addition, there is a vinyl analogue with imitation timber. It can have different shades besides natural wood tones.

Due to the synthetic basis, it is inert to insects, allows use in different temperature conditions. According to the manufacturers, it is resistant to various environmental conditions and is not afraid of an aggressive environment. This is a durable material, since its service life reaches 50 years. In comparison with the traditional counterpart, it is lighter in weight, characterized by a lower load on the foundation.

Scope of application

Block house under a bar used for exterior and interior walls.Depending on the chosen stylistic decision of a particular room or structure, it is used for covering of country houses, summer cafes, playgrounds and other facilities for mass leisure. It is applicable for the exterior cladding of baths and saunas, can decorate the walls of private houses inside the premises.

This is a good background for closed verandas and gazebos. In addition, this material can be used for covering bay windows, loggias and balconies, equipping them with comfortable work rooms or secluded resting places. A block house can be sheathed from the inside attic space.

However, in each case it is worth considering the fact that this skin is original. Its abundance inside structures can create an unpleasant effect of gravity and precariousness.

How to choose?

The choice of profile for finishing the house should be taken very carefully. Not every buyer knows that the purchase of lining with imitation timber must be carried out in advance. This is necessary in order to adapt the profile to the climatic conditions of the region. Usually, the lamellae are enough for a week to acclimatize, which will prevent the material from cracking in the future.

It is important to consider that as far as possible inspect every element. This is due to the fact that not always the storage conditions meet the standards. For example, in stores sometimes sell goods with an arc. This marriage is not suitable for purchase, since such a board will not keep well at the designated place and may come out of the castle joint.

The buyer can find out the percentage of moisture in the lamellae in the store. To do this, contact the seller. It should have a special tool through which you can find out if there is excess moisture in the selected block house. In this case, it is possible to take into account the fact that the humidity coefficient of a different type of profile may differ. If it does not exceed 15%, the product is good and will not crack in length during further use.

Choosing the type of material for the walls, you need to proceed not only from the cost, but also to build on the safety requirements, as well as to acquire it, taking into account reviews of the type of material. For example, high-quality vinyl block house should be painted on both sides.

With regards to the choice, it is better to purchase not the option that is cheaper, but the one that does not have a marriage initially.From this will depend on the final result of the skin.

For the best mounting block with imitation timber and modern wood mounting technology, see the following video.