Blockhouse finishing: material advantages and installation rules

Finishing of buildings provides for the use of modern plating, thanks to which the structure not only acquires a beautiful appearance, but also reliably protects itself from heat losses. In the construction market, you can purchase various materials for tiling, but block-house deserves special attention. The material is characterized by high performance. It is easy to install, perfectly emphasizes the style of any architectural structure, giving it chic and individuality.

Features and specifications

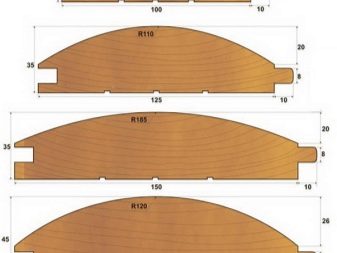

Block house is a unique decorative material. It comes in the form of planks with a flat inner and convex outer side. Also in the device of the product includes docking parts (spikes and grooves), which provide a secure fit, allowing the installation to avoid the formation of gaps and cracks.For the manufacture of a block house they use various wood, but most often they choose raw materials from deciduous and coniferous trees, which are characterized by excellent aesthetic qualities, hardness and strength.

Boards in the production process are of high-quality processing, so they are adapted for installation in any conditions. The main feature of the material is that during operation it does not crack. This is due to the fact that in the manufacture of the block house it is equipped with special grooves that relieve stress from the tree.

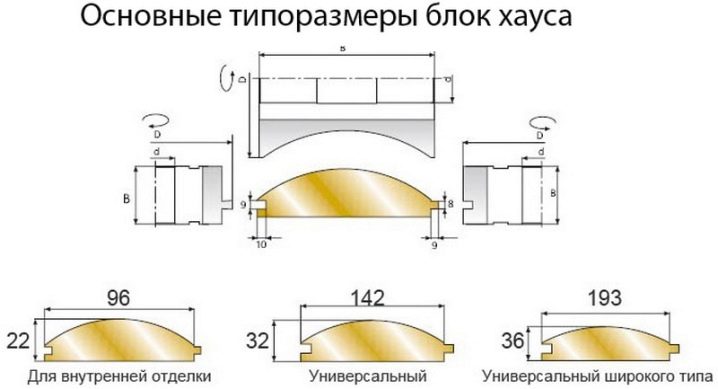

The material is produced in various sizes, which makes it possible to use it for both internal and external decoration. Interior cladding is usually performed using a wooden block-house with a cross section of 46 * 180 mm, and metal or vinyl panels are used for finishing buildings outside.

The main characteristic of boards is their class, which is determined by the quality of wood and the way it is processed.

Therefore, the sale can be found products of two options.

- Block house of the highest category. It is considered the highest quality, designed mainly for exterior plating.Such boards are characterized by the absence of chips and holes.

- Simple panels. Such products have a lower price, so often on the surface of such boards can be found light "fringe" or "fleecy".

It is also worth noting that the block house has a different thickness of panels, ranging from 20 mm to 50 mm. In this case, the minimum width of the boards is 70 mm, and the maximum - 190 mm. Before installing decorative wood panels, they must be carefully processed: primed and coated with several layers of varnish or paint. After drying, the painted wood is ground and covered with a protective layer, which must be renewed every 5 years.

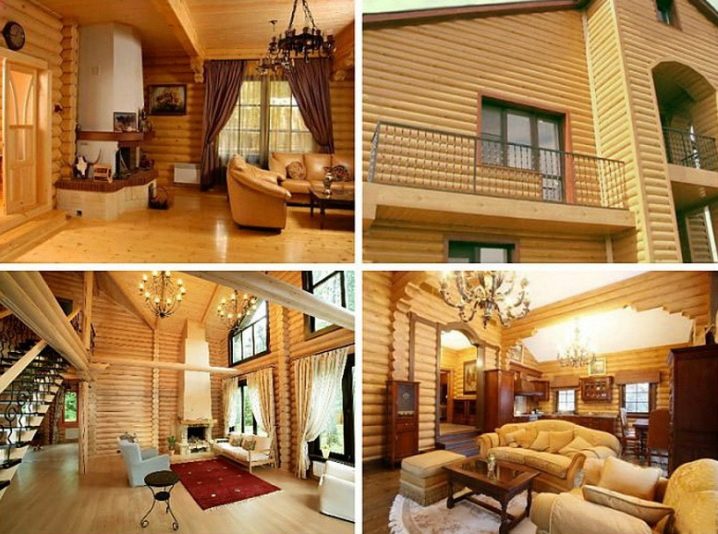

Since the block house is available in a rich assortment of colors and textures, it can be used for covering all types of premises and buildings.irrespective of style direction. Especially beautiful in this design look country houses. The decoration is a real decoration of landscape design. If you sheathe the material inside the building, you get an unusual effect, thanks to which the interior will be filled with comfort and homely warmth.

Types: advantages and disadvantages

Since the block house is made from various raw materials, it is divided into several types. The most popular material is made of natural wood. The main advantage of such boards is their environmental friendliness. The basis of the wooden block-house can be spruce, pine or larch, therefore, choosing it for external covering of the house, you can get an unusual decor with imitation of a log house.

Depending on the quality of the array, wooden panels are divided into three groups.

- Class "C". Boards have a well-groomed surface, no knots and other major defects. However, for these products a slight darkening, chipping and scratching are allowed.

- Class "B". The canvases are characterized by a low price, so there may be traces of mechanical damage on their surfaces, light and dark knots.

- Class "Extra". The boards are perfectly processed and free from any flaws. They are expensive, since they are characterized by high quality, which is achieved by the manual selection method.

Regardless of the class of production, the following advantages of a wooden block house can be highlighted:

- good heat and noise insulation;

- presentable appearance;

- naturalness

As for the negative properties, such boards are expensive, they easily catch fire and require treatment with antiseptics.

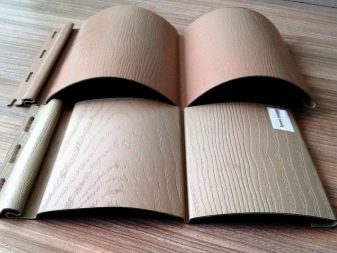

If you plan to budget option finishes, then the right choice would be vinyl panels. They are sold at an affordable price, imitating natural wood. The main advantage of the products is that before installation they do not need to be additionally impregnated with antiseptics and varnished. In addition, compared with wood, they have a longer service life and do not require special care. Since the vinyl block house is lightweight, it does not exert pressure on the structure of the building.

The advantages of vinyl panels include:

- a huge selection of textures and colors;

- ease of installation;

- durability;

- resistance to moisture and ultraviolet.

Such material has few disadvantages: it is sensitive to temperature changes, requires adherence to a special installation technology, and the surface of such boards looks duller than an array.

A steel block is also considered to be a no less popular type. It represents the bent profile painted under a natural tree.Thanks to this material, it is possible not only to decorate the facades, but also to provide high-quality thermal insulation. The main advantage of the product is its overstrength, but similar to vinyl panels, the material is only suitable for exterior decoration, since it looks unpresentable inside the premises.

The advantages of steel panels include:

- long service life;

- affordable price;

- ease of installation;

- moisture resistance and fire safety.

However, despite the positive characteristics, steel elements have disadvantages. They quickly heat up in the sun, and their installation requires the use of additional components.

Criterias of choice

The construction market impresses with a huge range of block-houses, but in order to perform a high-quality finish, it is necessary to choose the right material.

The product must not only have a beautiful appearance, but also have operational characteristics that allow it to last a long time.

- A huge role in the choice of panels is their width. For facades, it is better to choose a board with a minimum width of 159 mm, and for interior decoration - 80 mm.For wall cladding in rooms, the use of wide panels is not recommended, as they visually reduce the area of the room.

- Particular attention should be paid to the wood species from which the material is made. Larch is suitable for exterior work; it is resistant to moisture, has an original texture and color. When finishing inside buildings, it is best to give preference to linden or oak. They provide excellent waterproofing and insulation of the room.

- Choosing a block house, you also need to specify the class of its wood. The perfect trim can only be obtained from high-quality panels of the highest category. Therefore, all boards should be packed in one piece, have the same width and length. The purchase of material on the surface of which there are cracks, knots and tar spots is not allowed.

- It is recommended to buy boards with a length of at least 6 m, this will reduce the number of joints during installation.

- If the products do not have certificates, and the humidity of the boards exceeds 20%, then they cannot be used for finishing.

Preparation and accessories

Before the start of installation work, the block house should be prepared. For this, a short period of time is allocated for the acclimatization of the material. It usually takes a few days.At this time, outside the walls are placed insulation, waterproofing and make the calculation of the material in the cube.

Also, the installation of panels provides for the assembly of vertical battens from battens or bars. The distance between the frame elements should be 70 cm. In order to provide the necessary waterproofing, a thin frame is additionally attached to the screws over the insulated sheathing.

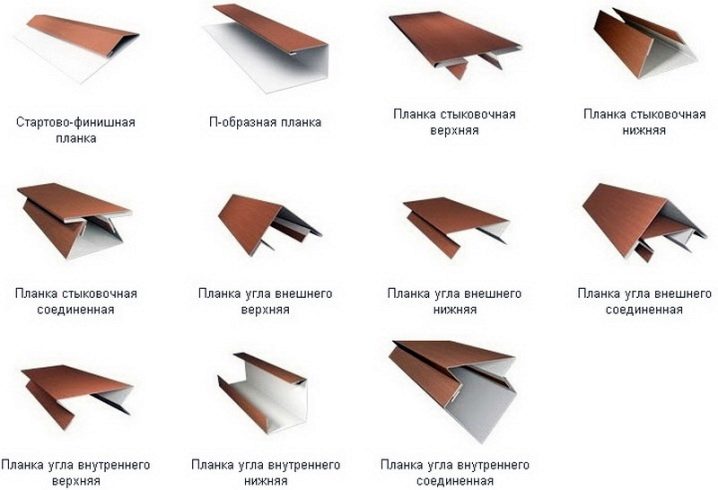

To install the boards you need to purchase certain components.

- Universal straps.

- Hinged profiles. Their fastening is carried out, as a rule, over window openings in order to protect the finish from moisture. If the facade consists of several levels, then profiles are used between transitions.

- Starting plate. It is necessary for mounting the bottom row of boards.

- Finishing profile. It is placed on the edges of the wall for fixing the latest panels.

- Connecting strips and corners.

- Special fastening elements (klyaymer and screws).

Tools for installation should consist of a standard set that includes a tape measure, level, screwdriver, hammer and drill.

Technology and installation rules

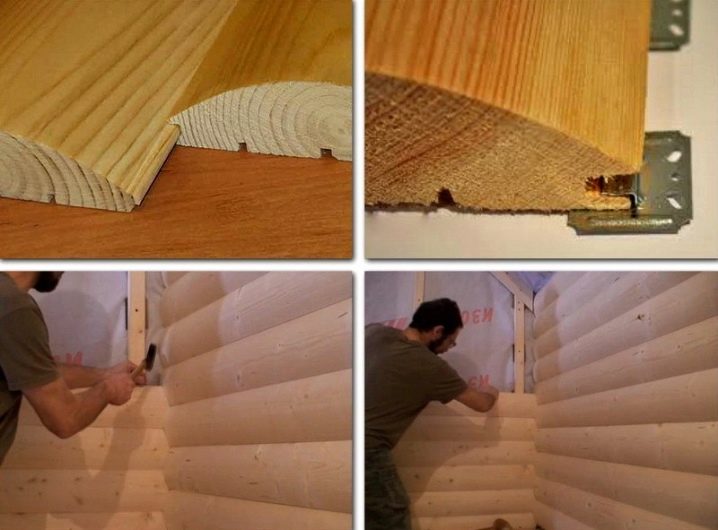

When the crate is made, it will be possible to start mounting the block-house panels.Laying the material is an easy process, so the work can be done independently, without the help of experts.

To install correctly, it is enough to follow the installation rules. It is also important to ensure a strong fixture finish. Boards to the frame must be fixed with metal brackets or cleats. If facing is carried out by thick panels, it is recommended to use self-tapping screws coated with an anti-corrosion compound.

Installation of the panels begins with the fact that they are laid out in a room so that the spike of each part is on top and the groove is on the bottom. This simplifies further workflow and reduces the risk of dust in the slots. It is important to provide a small gap between the ceiling, the floor surface and the cladding to ensure natural ventilation. You also need to leave gaps between the panels themselves, when they dock. This is done to ensure that the skin is not subjected to deformation when temperature drops and when moisture gets on its surface.

It should be noted that the exterior of the facade requires the availability of additional materials such as insulation, antiseptic, primer and vapor barrier film. Before covering the house block house you need to install a vapor barrier.Work is carried out using staples and a stapler, with which the film is fixed to the frame, forming an overlap of 10-15 cm.

If the block house is mounted horizontally, then first of all it is necessary to sheathe the bottom corner. The panel is installed on the profile and fixed along the entire length of the klyimer, which, in turn, is attached to the crate with self-tapping screws. Then the second panel is inserted into the cutters, its groove should “look” down.

Observing the above technology, you should sheathe the entire wall. In some cases, the installation of the material is carried out not klyimery, and screws. In this case, it is important to accurately dock the panel, screwing screws at a 45 degree angle.

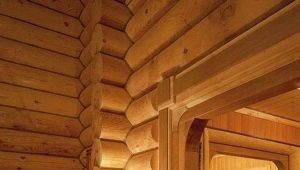

As for the design of the corners inside, they are decorated with a bar of 5 × 5 cm or with special plinths. In this case, experts advise to install the bars to the skin. Thanks to this, the finish is more attractive.

We must not forget about the facing of window and door openings. The most important thing is to protect them from dust, precipitation and cold air. It is better to choose platbands with carved patterns or unusual patterns. They can be figured, rounded or flat.

It looks interesting block house in the interior of residential premises.

This skin is almost no different from the outer lining, but is characterized by its nuances:

- for use usually rather narrow panels;

- internal and external corners are made at the end of the entire installation.

The use of a block house for decorating walls in rooms with high humidity is not recommended. If the style provides for the presence of panels in the bathroom or in the kitchen, then they must be covered with a protective layer of varnish. To extend the life of such plating, it should also be treated with mastic and stain.

Interior finish is desirable to periodically update. To do this, every 5-7 years, it is applied a protective layer, previously removing the old coating. The walls of the premises can be sheathed boards both vertically and horizontally.

Is it possible to make yourself?

Despite the fact that the modern market is represented by a chic assortment of blockhouse, many owners of suburban housing prefer to make it with their own hands, rather than buy it in finished form. At first glance, this may seem complicated, but if you have a small workshop and a woodworking machine on hand, the process turns out to be quite feasible.

In the conditions of the home workshop, you can produce several types of panels: with imitation of a bar, lining and evrooski. Since the types of wooden block house are not much different from each other, it is possible to produce panels of various designs without additional financial costs.

The process of self-manufacturing block house is carried out according to a certain scheme.

- First is the purchase of raw materials. It is better to choose class A or B wood. Both coniferous and deciduous species can be used to make boards. The main thing is that the wood be of high quality and free from defects in the form of chips and cracks.

- Then the log is cut into parallel bars. The sizes of future panels can be different, it all depends on personal preferences.

- The next stage is drying. Wooden blanks are placed in special chambers, where they remain until the desired level of humidity.

- After there is cutting grooves and spikes, after which the semi-finished product turns into a finished product. Board re-trimmed in length.

- The final stage is packaging. The resulting panels are sorted and placed in a thermal film.

According to such an algorithm, it is possible to make decorative boards both for one’s own needs and for sale, which opens up opportunities for additional earnings. The cost of panels depends on the degree and quality of wood processing. For example, if you grind material not only from the front, but from both sides, then its release will cost much more. In addition, the production of equipment to the block-house will require the availability of additional machines. The price of boards will also increase after they are treated with protective agents and antiseptics.

Considering the aforesaid, before the organization of independent production of a block house it is worth preparing the estimate and to calculate financial expenses. In addition to the acquisition of raw materials you will have to equip the home workshop with the necessary equipment. Usually, a four-sided machine and a milling cutter are required, the quality and type of panels will depend on the installation of which. If the machine is not purchased with a complete set of cutters, then they can be purchased separately. It is better to use automated equipment, but it is worth considering that such a purchase will be expensive and will entail considerable energy costs.

About what preparatory work includes finishing the house with a block house, see the following video.